Titanium exhaust systems are popular for their strength, durability, and lightweight design, offering significant advantages over steel alternatives in terms of performance, fuel efficiency, and sound. Welded systems provide superior structural integrity for extreme conditions, while bolt-on designs offer customization and ease of maintenance. These systems excel in high-performance vehicles, racing, and off-road use due to their corrosion resistance, weight savings, and efficient gas flow, enhancing power and dynamics without compromising safety.

Choosing between welded and bolt-on titanium exhaust systems depends on your needs. This comprehensive guide explores the intricacies of titanium exhaust systems, highlighting key differences between welded and bolt-on designs. We delve into applications, performance considerations, and more, to help you make an informed decision for optimal vehicle enhancement. Learn about the benefits and drawbacks of each option in the context of titanium exhaust technology.

- Understanding Titanium Exhaust Systems

- Welded vs. Bolt-On: Key Differences

- Applications and Performance Considerations

Understanding Titanium Exhaust Systems

Titanium exhaust systems have gained popularity among automotive enthusiasts for their exceptional strength, durability, and lightweight properties. This type of exhaust system is a significant upgrade from traditional steel or stainless steel setups, offering improved performance and efficiency. Titanium’s high specific strength means it can withstand extreme pressures and temperatures without compromising integrity, making it ideal for high-performance vehicles. These systems also contribute to reduced weight, enhancing fuel economy and overall vehicle handling.

When considering a titanium exhaust system, you’re not just investing in better performance; you’re choosing a long-lasting solution that reduces maintenance needs. Unlike traditional bolt-on or welded configurations, titanium exhausts often feature advanced design elements, such as optimized turbine geometry and carefully engineered intake components, ensuring efficient gas flow and maximizing the potential of your engine. This focus on craftsmanship translates to superior sound quality, too, with many owners appreciating the unique and powerful note that a well-designed titanium exhaust can produce, setting their vehicles apart from the crowd, especially when compared to standard brake rotors or even performance exhausts made from other materials.

Welded vs. Bolt-On: Key Differences

When considering a titanium exhaust system, understanding the differences between welded and bolt-on designs is crucial for making an informed decision. Welded titanium exhaust systems involve joining components together through welding, creating a seamless and robust structure. This method offers superior strength and durability, ensuring the exhaust can withstand high temperatures and pressures. The welds provide a strong bond, enhancing the overall performance and longevity of the system.

In contrast, bolt-on exhaust mufflers utilize fasteners to attach the components, providing an easier installation process. While they may not match the welded design’s structural integrity, they offer flexibility in terms of customization and maintenance. Bolt-on systems are often preferred for those seeking a more affordable option or who require quick modifications, as they allow for relatively simple removal and replacement of individual parts, such as air filter kits or suspension kits.

Applications and Performance Considerations

When considering a titanium exhaust system, applications and performance are key factors to evaluate. Titanium exhaust systems are often chosen for high-performance vehicles due to their exceptional strength-to-weight ratio and superior corrosion resistance compared to traditional materials. This makes them ideal for racing or off-road vehicles where durability and weight savings are paramount. The efficient flow of gases through titanium allows for improved vehicle performance, enhancing power output and torque while reducing backpressure in the engine.

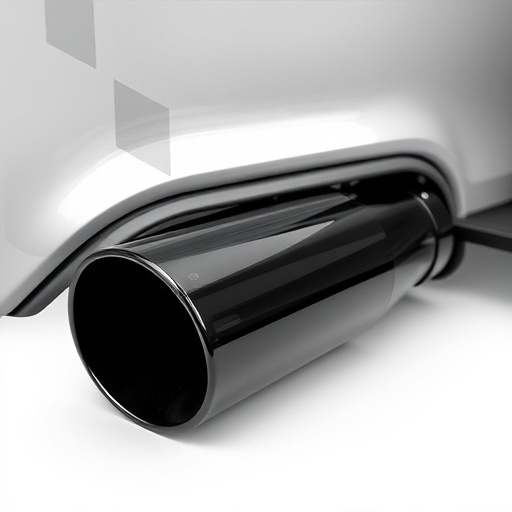

Furthermore, the versatility of titanium exhaust systems is evident in their ability to customize exhaust tips and configurations based on specific vehicle needs. Unlike bolt-on systems that primarily focus on direct attachment, welded titanium exhausts offer more intricate designs, allowing for better sound tuning and potentially improved flow dynamics. These considerations are crucial when optimizing both engine sound and overall vehicle performance, ensuring the titanium exhaust system enhances the driving experience without compromising safety, especially in comparison to other components like brake rotors which require regular maintenance.

When deciding between welded and bolt-on titanium exhaust systems, understanding their distinct features is key. Welded systems offer seamless integration and superior strength, ideal for high-performance applications demanding robust durability. Bolt-on systems, however, provide ease of installation and removal, making them a popular choice for those seeking versatility. In terms of performance, both excel in weight reduction and improved gas flow, contributing to enhanced engine efficiency. Ultimately, the choice depends on individual needs, whether it’s track days or everyday driving, ensuring your titanium exhaust system aligns with your vehicle’s unique requirements.