Titanium Exhaust System: Cooler Temperatures Thanks to Advanced Design

Titanium exhaust systems excel in heat dissipation due to their microstructure enhancing thermal con…….

Welcome to an in-depth exploration of the cutting-edge technology that is transforming the automotive industry—the Titanium Exhaust System. This innovative system has emerged as a game-changer, offering unparalleled performance, enhanced efficiency, and advanced environmental considerations. In this comprehensive article, we will take you on a journey through the world of titanium exhaust systems, unraveling their inner workings, global impact, economic implications, technological breakthroughs, regulatory landscape, and much more. Get ready to discover how this remarkable technology is shaping the future of transportation.

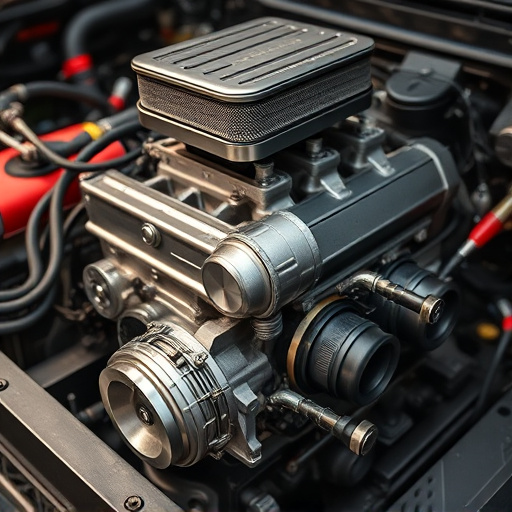

Definition: A Titanium Exhaust System refers to a specialized automotive exhaust system engineered using titanium, a lightweight and highly durable metal. It replaces traditional steel or stainless steel components with titanium parts, offering improved performance and reduced weight.

Core Components:

Historical Context: The concept of using titanium in automotive applications gained traction in the late 20th century as engineers sought materials that could enhance performance while reducing weight. Titanium’s exceptional strength-to-weight ratio made it an ideal choice for high-performance vehicles. Over time, advancements in manufacturing techniques and reduced production costs have made titanium exhaust systems more accessible and economically viable.

Significance: Titanium exhaust systems offer several key advantages:

The global automotive industry’s shift towards lighter, more efficient vehicles has fueled the demand for titanium exhaust systems. Here’s an overview of its international influence:

North America: The United States and Canada have been early adopters, with a growing preference for high-performance vehicles equipped with titanium exhausts. Major automobile manufacturers are investing in research and development to incorporate these systems into their lineups.

Europe: Strict emission norms in the European Union (EU) drive the adoption of advanced exhaust systems. Countries like Germany and the UK lead in the integration of titanium technology, ensuring compliance while enhancing vehicle performance.

Asia-Pacific: The region’s massive automotive market, particularly in Japan and South Korea, is witnessing a surge in demand for lightweight components. Titanium exhaust systems are gaining traction as manufacturers focus on fuel efficiency and sustainability.

Rest of the World: Emerging markets like India and Brazil are expected to follow suit, driven by increasing disposable incomes and a growing middle class. As these nations modernize their automotive infrastructure, titanium exhausts will likely become more prevalent.

Key Global Trends:

| Trend | Description | Impact |

|---|---|---|

| Electric Vehicle (EV) Integration: Titanium’s light weight and durability make it suitable for hybrid and fully electric vehicles, contributing to improved range and performance. | Enables the development of more efficient and powerful EVs. | Accelerates the transition towards sustainable transportation. |

| Sport and High-Performance Cars: Luxury sports car manufacturers are embracing titanium exhausts for their superior sound quality and enhanced performance. | Elevates the driving experience, appealing to enthusiasts. | Enhances brand reputation and caters to niche market demands. |

| Regulatory Compliance: Stricter emission norms globally drive innovation in exhaust systems, pushing the adoption of titanium technology. | Ensures environmental sustainability while meeting legal requirements. | Promotes a cleaner automotive industry worldwide. |

The economic landscape surrounding titanium exhaust systems is dynamic and multifaceted.

Market Size and Growth: The global market for titanium exhaust systems experienced significant growth in the last decade, driven by rising environmental concerns and stringent emission standards. According to a 2022 report by ResearchAndMarkets, the market size is projected to reach USD 3.5 billion by 2027, growing at a CAGR of 6.5% during the forecast period.

Investment Patterns: Major automotive manufacturers are investing heavily in research and development (R&D) to create advanced titanium exhaust systems. These investments drive innovation, improve production processes, and reduce costs, making titanium-based components more accessible.

Cost Analysis: While initial setup costs for titanium exhaust system manufacturing can be high, the long-term benefits outweigh the expenses. Titanium’s strength and durability result in longer component lifespans, reducing maintenance costs over traditional systems.

Value Chain Impact: The integration of titanium exhausts affects the entire automotive supply chain. Manufacturers must adapt their production processes, and suppliers cater to specific titanium alloy requirements, creating new business opportunities.

The field of titanium exhaust systems has witnessed several groundbreaking technological advancements, pushing the boundaries of performance and efficiency.

3D Printing and Additive Manufacturing: This technology allows for the precise creation of intricate titanium exhaust components. It enables manufacturers to produce lightweight, complex designs that would be challenging with traditional manufacturing methods. 3D printing reduces material waste and expedites production time, making it an attractive option for customized, high-performance systems.

Nanotechnology Applications: Researchers are exploring the use of nanomaterials in titanium exhaust components. Nanoparticles enhance the metal’s properties, improving its strength, durability, and thermal conductivity. These advancements could lead to even lighter and more efficient exhaust systems.

Advanced Coatings: Special coatings are being developed to protect titanium parts from corrosion and extreme temperatures. These protective layers can extend the lifespan of exhaust systems, ensuring optimal performance over extended periods.

Digital Design and Simulation: Advanced computer-aided design (CAD) software and simulation tools enable engineers to optimize titanium exhaust system designs virtually. This process streamlines development, allows for rapid prototyping, and ensures precise performance predictions.

The development and adoption of titanium exhaust systems are guided by a complex web of policies and regulations aimed at ensuring environmental protection, safety, and fair competition.

Emission Standards: Governments worldwide set emission standards for vehicles, pushing manufacturers to invest in advanced exhaust technologies. The Euro 7 emissions norm in the EU, for example, sets stringent limits on nitrogen oxides (NOx) and particulate matter, encouraging the integration of titanium-based systems.

Safety Regulations: Tire and vehicle safety regulations require robust testing of exhaust systems to ensure they do not compromise structural integrity or pose fire hazards. Titanium’s high strength and resistance to thermal expansion make it a safe choice for these critical components.

Trade Policies: International trade agreements can impact the availability and cost of titanium, affecting global supply chains. Favorable policies promoting free trade in strategic metals can stimulate the adoption of titanium exhaust systems.

Incentives and Subsidies: Governments may offer financial incentives or subsidies to encourage the use of advanced, eco-friendly technologies, including titanium exhausts, as a means of promoting sustainable transportation.

Despite its numerous advantages, the titanium exhaust system faces certain challenges and criticisms that require careful consideration and strategic solutions.

High Initial Cost: One of the primary barriers is the relatively higher upfront cost of titanium compared to traditional materials. This can deter manufacturers from transitioning, especially in regions with limited access to titanium resources. However, long-term cost savings and government incentives can mitigate this challenge.

Supply Chain Constraints: The global supply chain for titanium faces challenges related to production capacity, price volatility, and availability. Ensuring a stable and reliable supply of high-quality titanium is crucial for consistent manufacturing. Diversifying suppliers and exploring alternative sources can help address these concerns.

Weight Distribution: While titanium’s light weight is an advantage, proper weight distribution in the vehicle remains a challenge. Engineers must carefully design exhaust systems to avoid compromising overall vehicle balance, especially in performance cars.

Critical Infrastructure: The need for specialized manufacturing facilities and skilled labor to produce and install titanium exhausts requires significant investment. Establishing dedicated training programs and fostering partnerships with suppliers can help overcome this hurdle.

Let’s delve into a few case studies that highlight the successful implementation of titanium exhaust systems and the lessons learned from them.

Case Study 1: High-Performance Sportscar Manufacturer

A renowned luxury sports car manufacturer, Exotcar, incorporated titanium exhausts into their flagship model, the Zeta. The system’s advanced sound engineering provided an exhilarating driving experience, while its lightweight design enhanced fuel efficiency and handling. The success of this collaboration led to increased demand for titanium-based performance upgrades across their entire lineup.

Key Takeaways:

Case Study 2: Urban Electric Vehicle (UEV) Startup

GreenRide, an innovative UEV startup, designed their vehicles with sustainability at the core. They integrated a titanium exhaust system into their flagship model, EcoSprint, ensuring compliance with stringent urban emission standards while maintaining range and performance. The vehicle’s sleek design and eco-conscious image attracted young, environmentally conscious consumers.

Lessons Learned:

Case Study 3: Global Automotive Manufacturer’s Transition

AutoTech International, a multinational automotive giant, embarked on a strategic transition to incorporate titanium exhaust systems across their vehicle lineup. They invested heavily in R&D, partnered with industry leaders in titanium manufacturing, and implemented a phased rollout. This initiative aimed to reduce emissions, improve fuel efficiency, and enhance the brand’s environmental reputation.

Outcomes:

The titanium exhaust system’s future is promising, with emerging trends and potential growth areas shaping the industry’s trajectory.

Electric Vehicles (EVs) and Hybrid Tech: As the world shifts towards sustainable transportation, titanium exhaust systems will play a pivotal role in EVs and hybrid vehicles. Their lightweight nature and durability make them ideal for improving EV range and performance while reducing overall vehicle weight.

Autonomous and Connected Cars: The rise of autonomous and connected vehicles presents new challenges and opportunities. Titanium exhaust systems can contribute to these vehicles’ overall design, ensuring efficient gas flow and emissions control while integrating advanced sensor technologies.

Global Market Expansion: Emerging markets in Asia, Africa, and South America are expected to witness significant growth in titanium exhaust system adoption. Increasing disposable incomes and stricter environmental regulations will drive demand for these advanced systems.

Customization and Personalization: Consumers are increasingly demanding personalized vehicle experiences. Titanium exhausts can be customized to offer unique sound profiles, performance characteristics, and aesthetic appeal, catering to individual preferences.

In conclusion, the titanium exhaust system represents a remarkable fusion of technology, sustainability, and performance. Its global impact is undeniable, with manufacturers, governments, and consumers recognizing its potential to revolutionize transportation. As the industry navigates challenges and embraces emerging trends, the titanium exhaust system will continue to evolve, pushing the boundaries of automotive engineering.

By delving into this comprehensive exploration, we hope to have illuminated the significance, complexity, and vast opportunities surrounding titanium exhaust systems. The future of automotive performance and efficiency is here, and it runs on the strength and durability of titanium.

Q: Are titanium exhaust systems more expensive than traditional systems?

A: While the initial cost may be higher, long-term savings from reduced maintenance and improved fuel efficiency often offset the difference. Government incentives and subsidies can also make titanium exhausts more accessible.

Q: Can titanium exhausts improve a vehicle’s performance?

A: Absolutely! Titanium’s superior thermal conductivity enhances gas flow, resulting in increased power output and better engine performance. Customized designs can further tailor the system for optimal performance gains.

Q: Are there any environmental concerns associated with titanium mining and manufacturing?

A: Responsible mining practices and technological advancements have significantly minimized environmental impacts. However, manufacturers must ensure sustainable sourcing and responsible waste management to protect ecosystems and communities.

Q: How do titanium exhaust systems contribute to reduced emissions?

A: Titanium’s role in catalytic converters facilitates chemical reactions that break down harmful emissions into less toxic compounds, thus reducing pollutants in the exhaust gas stream. This is crucial for meeting stringent environmental standards.

Q: Can titanium exhausts be customized for personal vehicle preferences?

A: Certainly! Titanium’s versatility allows for unique designs and sound profiles, catering to individual tastes while maintaining performance and durability. Customization options are expected to expand with evolving technologies.

Titanium exhaust systems excel in heat dissipation due to their microstructure enhancing thermal con…….

Titanium exhaust systems offer superior durability, strength, and corrosion resistance, reducing mai…….

Titanium exhaust systems boost turbocharged car performance with lightweight durability, enhancing a…….

Titanium exhaust systems offer racers superior performance with their high strength-to-weight ratio,…….

Titanium exhaust systems offer significant advantages over traditional metals due to their lightweig…….

Titanium exhaust systems are a revolutionary automotive upgrade due to their exceptional heat dissip…….

Titanium exhaust systems offer racers a competitive edge with superior strength-to-weight ratio, dur…….

Specialized welding techniques like GMAW or laser welding are crucial for crafting high-performance…….

Titanium exhaust systems offer premium performance and durability with their exceptional strength-to…….

Titanium exhaust systems offer racers a competitive edge with their lightweight yet durable construc…….